Russian supply concerns weigh on plane makers’ Covid recovery

Simply sign up to the Aerospace & Defence myFT Digest -- delivered directly to your inbox.

Large aircraft orders have been few and far between since the coronavirus pandemic caused the grounding of most of the global fleet — and triggered one of the worst crises for the industry in decades.

But, at the start of this month, a bulk order by China’s state airlines for close to 300 Airbus single-aisle A320neo aircraft, worth some $37bn — the first order by the country’s carriers since the start of the crisis — provided the latest sign that the industry is recovering and returning to health.

More aircraft orders are expected to be announced this week by both Boeing and Airbus when the industry gathers at the world’s second-biggest air show, at Farnborough in Hampshire, in the UK.

Both manufacturers — as well as a host of electric air taxi start-ups promising urban air mobility — will also showcase their environmental credentials as the industry seeks to deliver on a pledge to reach net zero emissions by 2050.

Entrepreneurs behind the likes of Joby Aviation, Vertical Aerospace and Lilium, which are targeting scaled deployment of their flying taxis between 2023 and 2025, will all be present. And Boeing’s joint venture, Wisk Aero, will make the European debut of its all-electric vertical take-off and landing air taxi at the show.

One notable absence from this year’s show, however, will be the Russian aircraft industry, in the wake of the country’s invasion of Ukraine. But the war has prompted western governments to reverse years of cuts to their defence budgets. Aerospace and defence executives will be discussing the longer-term implications for their businesses, amid expectations of more contracts.

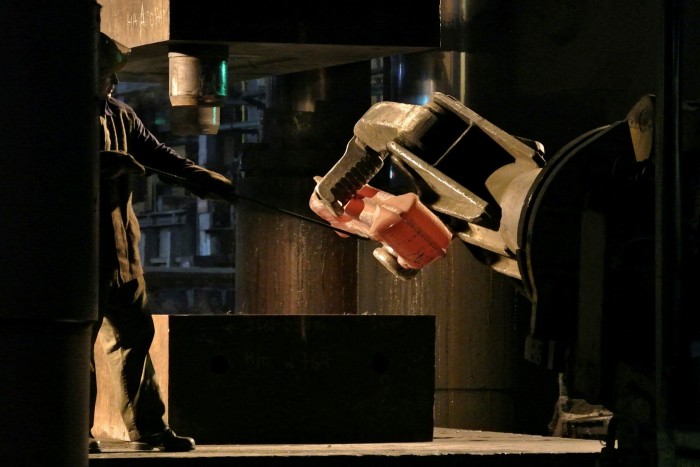

Despite a more buoyant mood fuelled by recovering demand for new planes from airlines keen to renew their fleets, the industry still faces a challenging operating environment. Soaring inflation, and concerns over the supply of important commodities such as aluminium and titanium in the wake of Russia’s invasion of Ukraine, pose ongoing problems for manufacturers.

Titanium is used to make critical components for aircraft, including landing gear as well as fasteners to the pylons that join an engine to a wing. Both Boeing and Airbus have relied on Russia for a large proportion of their supply of the metal. Although titanium has so far been kept off EU and US sanctions lists against Russia, aircraft companies have tried to reduce their exposure and looked to source alternative supplies.

Uncertain availability of parts and of skilled labour have been among the top two concerns cited by industry executives in recent months, according to David Stewart, partner at consultancy firm Oliver Wyman.

Aerospace groups, he says, are facing a “double pinch of volatility” in supply, coming out of the pandemic. “The new normal is to be really agile and to understand the demands of your supply chain. That volatility, whether for parts or labour, is really a challenge for the industry.”

As a result, executives will be watching closely how Airbus — and its hundreds of suppliers — cope with the European company’s pledge to raise production of its best-selling A320 family of aircraft by 50 per cent, to a rate of 65 planes a month by next summer, and then 75 planes a month by 2025.

After slashing production during the pandemic, both Airbus and Boeing are having to respond to strong demand for their medium-sized jets.

Airbus plans to meet the higher output rates by increasing capacity at its existing industrial sites, including building a second final assembly line at its US operation in Mobile, Alabama.

Engine makers and aircraft leasing companies had pushed back against the company’s more aggressive “scenarios” last year. But Airbus has since agreed supply deals with engine makers Safran and MTU for delivery through 2024 — signalling an easing of tensions between the companies.

Even so, getting to the higher production rates will be a “real challenge,” says Kevin Michaels, managing director of Michigan-based consultancy AeroDynamic Advisory. “You’ve got bottlenecks all over the supply chain. In particular, the engine supply chain is really tight.”

Those constraints could yet increase once Boeing ramps-up production of its aircraft. Dave Calhoun, Boeing’s chief executive, recently said he expected the industry’s current supply chain issues to last until possibly late 2023.

The US company has continued to grapple with a series of production and certification issues around some of its models in the wake of two deadly crashes of its 737 Max single-aisle aircraft, its key money-spinner.

It told the FT that it is continuing to “make progress stabilising our 737 production rate at 31 planes a month”, adding that “we are balancing the need to increase the production rate to position us to support increasing demand longer-term”.

Asia, and notably China, where the domestic travel market has remained subdued due to ongoing Covid restrictions, remains the unknown factor in the industry’s recovery.

China is a critical market for Airbus and Boeing, accounting for some 25 per cent of the global aviation growth that the US company has forecast over the next decade.

This month’s order for Airbus planes from Chinese state airlines was the first since 2019. China Eastern Airlines said it would buy 100 of the popular single-aisle A320neo family of jets, Air China will take 64 of the aircraft, while its Shenzhen Airlines subsidiary is purchasing another 32. In addition, China Southern Airlines, a carrier Boeing has historically counted as its biggest customer in the country, said it will buy 96 A320neos, as well as lease additional planes.

But Michaels points out that China’s “air travel market has really lapsed”. What happens there next “is the big wild card to watch in all of this”.

Comments