Pivoting production eases pressure on pandemic-hit governments

Roula Khalaf, Editor of the FT, selects her favourite stories in this weekly newsletter.

Company supply chains and production lines have long been focused on providing goods promptly and efficiently. Yet over the past few months, the priority for a growing number has been reinvention — producing different products to help governments cope with the Covid-19 pandemic.

Fashion houses such as Burberry are making non-surgical gowns and masks. Breweries are making hand sanitiser as well as pale ales. Flight attendants with medical training have been seconded to hospitals.

Although pivoting production to alternative goods can be costly, such flexibility may result in fundamental changes — what lessons can this offer to companies and governments?

The cost of switching varies according to how different the new product is to the old — the bigger the difference the more expensive it will be, experts say.

Keeping some production lines and supply chains open during a pivot may help companies return to normal production quicker because “they are able to continue running core parts of their business”, says James Yearsley, a partner at consultancy Deloitte who specialises in supply chains and procurement.

BrewDog, a Scottish craft beer brewery, is making hand sanitiser for Britain’s NHS and other frontline workers. The sanitiser is produced voluntarily by some of the company’s furloughed bar staff who were working until March — when the UK government ordered the closure of bars — and staff in the company’s head office and refinery. Meanwhile, BrewDog has continued to brew beer and expanded its home delivery service.

“Covid-19 has shifted a lot more of our sales direct to consumer,” says James Watt, BrewDog’s co-founder.

BrewDog runs a chain of bars as well as producing beer, meaning that it will be especially affected by the Covid-19 lockdown. “We, like all other companies, are thinking what the landscape, post-Covid-19, will look like,” says Mr Watt. “How long does it take to come back to how things were? Does it ever come back like that? Or does it come back differently? At least for the rest of this year and into next year people are predominantly going to be a bit reluctant to go out to the same extent that they did before.”

For large companies, it is likely to take weeks rather than months for production to return to normal levels, experts reckon.

Rebooting production lines should usually be fairly straightforward, because much of it is computerised, says Bob Sibik, co-founder of Fusion Risk Management, which advises companies on supply chains and business continuity. A programmer can reprogram the “computer aided design” that runs most manufacturing machines, such as 3D printers and laser cutters. “It will depend on what [a company] is manufacturing but they can retool in a couple of days,” says Mr Sibik.

A requirement for “social distancing” at work — keeping employees apart to reduce the risk of Covid-19 infections — will make it hard for employers to manage crowded workplaces. This is likely to mean companies will spend more on technologies that cut the need for human intervention in supply chains, Mr Sibik says.

More automation may result in job cuts, Mr Sibik says. However, workers will still be needed to monitor manufacturing systems, he adds, with staff who understand the technology being best placed to keep their roles.

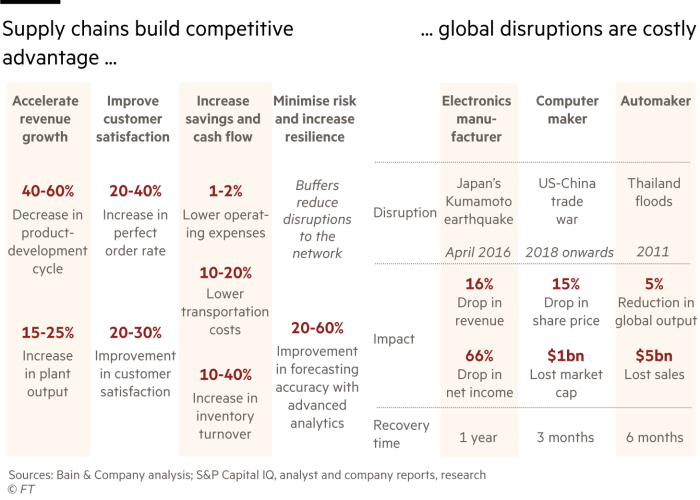

Covid-19 may even prompt companies to judge supply chains more on their resilience and reliability during a crisis, and less on their ability to minimise surplus stock and their efficiency of delivery. “Before Covid-19, just-in-time demand and no excess stock [in supply chains] was seen as desirable,” says Mr Yearsley. “In future, maybe excess capacity for supply chains will be seen as desirable because it builds buffers into supply chains to cover changes in demand.”

Governments may also review their supply chains after Covid-19.

“Governments are definitely thinking and worrying about [supply chain problems] a lot, most obviously in medical goods and PPE [personal protective equipment],” says Geoffrey Gertz, an expert in trade and foreign investment at the Brookings Institution, a US think-tank.

For example, the US government’s $2tn economic stimulus package in response to Covid-19 — known as the Cares Act — includes a call for the National Academies of Sciences, Engineering, and Medicine to audit the medical product supply chain to identify vulnerabilities, he adds.

Global crises can lead to positive changes, such as encouraging governments and companies to collaborate to better prepare for future shocks, says Creon Butler, research director at Chatham House, a London think-tank. “The advantage of a globally pooled approach is that you share information,” says Mr Butler. “If you are acting individually as countries or as companies, it is harder to produce the most efficient response.”

Comments