Tech and changing labour costs on course to transform shipping

Roula Khalaf, Editor of the FT, selects her favourite stories in this weekly newsletter.

Watching a truck pick up a container at London Gateway, a port 30 miles east of the UK capital on the Thames Estuary, it is easy to think the future has already arrived.

The driver parks his vehicle by the container stack, leaves the cab for a small shelter and presses a button. Cranes then move into action: they locate the relevant container, lift it from the stack and deposit it smoothly on the truck’s trailer — all without human intervention.

Yet the shipping and port industries are already planning new steps to make their role in delivering goods to consumers across the globe run even more efficiently over the coming decades. Tech is not the only disruption afoot: changes in global labour costs could also challenge the traditional shipping model.

More technology will be used at port terminals in future, according to Ernst Schulze, UK chief executive of DP World, the Dubai-based operator that built and runs London Gateway. “There will be more automation; more information technology will be used,” he says.

DP World has already formed a joint venture to develop BoxBay, a technology that will store containers in a new intelligent system, Mr Schulze says.

Currently at ports, containers are stacked on top of each other, making it difficult and time-consuming to retrieve those at the bottom of the pile. BoxBay would instead use a scaffolding-like structure so containers would not rest on each other, meaning they could be easily retrieved for delivery to trucks or ships.

This should eliminate the “inefficiencies” of the existing stacking systems and change the configuration of terminals, says Mr Schulze.

Further into the future, DP World is also looking at technology to support delivery. The company has joined the board of Virgin Hyperloop One, which plans to offer high-speed, magnetic levitation travel for passengers and high-value freight. These trains will run down low-pressure tubes at ground level.

The hope is to deliver the most urgent goods at the speed of aircraft but with far less environmental impact since the system runs on electricity.

“It’s not a replacement for anything else,” Mr Schulze says. “It’s more a new technology which is being tested to see if it would work.”

Alterations to the world’s trade patterns could bring just as much change to how goods move around the world as any technology, according to Tim Power, managing director of London-based Drewry Shipping Consultants.

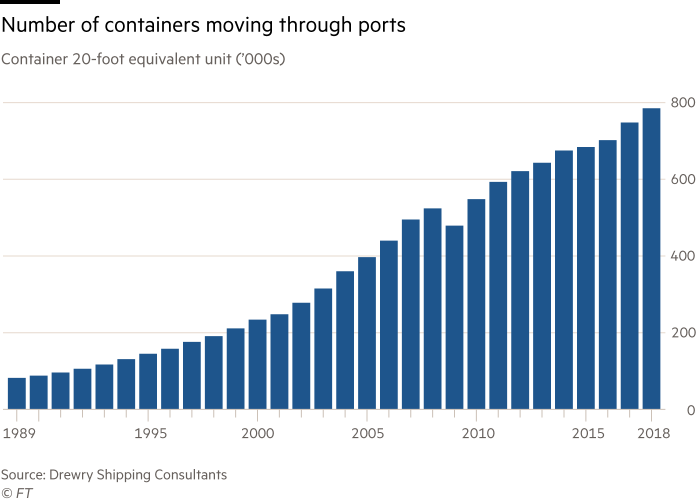

Traditionally, manufacturing has taken place in Asia where labour costs are lower. This has driven a growth in container shipping over decades as suppliers move goods long distances to markets. But expected advances in robotics should make the difference in worldwide labour costs far less of an issue in future, says Mr Power.

“What has driven it [the growth of container volumes] from the beginning is offshoring of manufacturing,” he says. If labour costs are no longer a factor, he adds, then trade may alter too.

At the heart of all these changes are the huge container ships that loom alongside the quays at London Gateway. Container lines purchased bigger vessels to benefit from efficiencies of scale when moving containers between Asia’s manufacturing hubs and Europe and North America.

Among the vessels regularly calling at London Gateway is the Cap San Artemissio, operated by Germany’s Hamburg Süd, measuring 333m in length, 48m in breadth and capable of carrying 9,600 20ft containers. The port is also designed to handle new, even larger vessels such as Mediterranean Shipping Company’s Gülsün, launched this year and capable of carrying 23,756 20ft boxes.

Ports around the world have scrambled to buy taller cranes and introduce more efficient container-handling systems to cope with such behemoths.

But Mr Power says the “biggest implication” of the potential decline in the importance of labour costs is that far less trade will be intercontinental, and far more will be shorter-distance, regional traffic. Manufacturing for western Europe could be focused in eastern Europe or Turkey, while manufacturing for the US and Canada is likely to centre on Mexico.

That will put the emphasis on vessels that are quick to load and unload, rather than ones that can carry boxes at minimal cost over thousands of miles. “You need more smaller ships, rather than very big ones, because they’re doing shorter trips,” Mr Power says.

Mr Schulze is sceptical that trade patterns will change radically. Much of the produce that London Gateway handles, for example, is food travelling in refrigerated containers from the tropics and southern hemisphere.

But a shift away from long-distance traffic would have significant implications for shipping. Smaller vessels making shorter journeys between ports could prove easier to convert to electric propulsion than the intercontinental giants, which are likely to rely on some kind of hydrocarbon fuel for the foreseeable future.

A shrinking in vessel size could also revive the fortunes of river ports that have been neglected as the ever-bigger vessels were unable to make river voyages. Such a shift could bring goods closer to the big population centres often found on rivers and eliminate some environmentally-expensive, on-land movements of goods by truck.

Some of those trends are already under way at London Gateway. In 2020, Rail Operations Group, a specialist engineering company, is planning to launch a rail service from the port to London’s Liverpool Street station. This will carry goods for logistics companies and retailers, avoiding the UK capital’s congested roads.

In addition, the port is examining the possibility of starting a barge service carrying containers to a new terminal on the Thames at Hurlingham, west London.

Such a service would replicate what already happens in much of mainland Europe. “If you go to continental Europe and look at the Rhine or Elbe rivers, there’s a lot of traffic,” Mr Schulze says. “They really use them.”

Yet, however much they expect change in the future, both Mr Power and Mr Schulze agree that there will also be some continuity, even 30 years hence. Neither sees an end in sight for the steel shipping container — a building block of the global logistics system that was standardised shortly after the first container ship voyage in 1956 and has survived ever since.

“It’s a very simple and logical concept and it’s worked very well,” Mr Power says.

Comments